Each Azur piece is the result of long and thorough research into quality materials and environmental best practices. No element is set aside and every step of the production process, every component of every piece, is carefully selected to align with Azur's values. Our starting point is always a material or know-how that we want to explore and highlight. We approach creation through local production and techniques that guide the visual language of each piece. Azur is deeply committed to building a transparent production chain, with responsibly sourced, natural materials in collaboration with local craftswo·men, promoting a wholesome, humanscale economy.

NATURAL DYEING

Our last collection is a colorimetric exploration of the dye plant Madder. With a single plant, we have conducted research on dyeing and developed a palette of rich and varied reddish shades. These pieces are a showcase of the color possibilities offered by a plant, which the dyer, like the painter, expresses and sublimates through their work. The dyeing is hand-made in Marseille (South of France) by Azur’s founders Lisa and Lisa.

The fundamentals of the dyeing process have not evolved much over time. Two to three steps are required to obtain the desired color. First, the fabric has to be prepared and requires the use of mordants to bind the dye to the textile fibres. This first bath prepares the fiber to obtain bright, lightfast and long-lasting colors for the second step : the dye bath. The next day the dye material is put in a water vat and heated to extract the dye compounds into solution with the water. Then the fabric is added to the bath and stirred during one hour to obtain a even result. Modifer or color shifting is the name given to a third optional bath that sadden bright shades and turns color into muted and darker tones.

Archaeologists have found evidence of textile dyeing dating back to the Neolithic period. In China, dyeing with plants, barks and insects has been traced back more than 5,000 years. Throughout history, people have dyed their textiles using common, locally available materials. The discovery of man-made synthetic dyes in the mid-19th century triggered a long decline in the large-scale market for natural dyes.

ORGANIC AND LOCALLY GROWN MADDER ROOTS

Madder (rubia tinctorum) has been used since ancient times as a natural red dye for silk, wool, cotton, and leather. For dye production, the roots are harvested after two years. The extremely brittle madder root grows randomly in the ground and has to be dug up by hand, as harvesting is difficult to mechanize. The roots are then cleaned, dried and ground into powder. Madder has been renowned since the dawn of mankind for its red color and robustness. A very intense red is obtained by saturating the plant, followed by orange and pink hues when used in smaller quantities, and brown by adding iron. This artisanal process takes from 1 to 3 days to complete.

The South of France has developed a strong relationship with this plant, dating back to the mid-19th century. From 1850 to 1870, Vaucluse region (South of France) produced a record 25,000 tons of madder a year, employing up to 180,000 farm workers. In 2018, two sisters, Amandine and Laura Roussier, took over their father’s family vegetable farm in La Roque d’Anthéron (South of France) to grow dye plants. We’ve been using their organic and locally grown plants in our collections since 2020.

Early evidence of dyeing comes from India where a piece of cotton dyed with madder has been recovered from the archaeological site at Mohenjo-daro (3rd millennium BCE). The oldest European textiles dyed with madder come from the grave of the Merovingian queen Arnegundis in Saint-Denis near Paris (between 565 and 570 AD).

The first synthetic dyes were discovered in the mid-19th century. Alizarin, the red dye present in madder, was the first natural pigment to be duplicated synthetically, in 1869, leading to the collapse of the market for naturally grown madder.

pictures: Le Champ des Couleurs

HAND PLEATING

Part of our first collection in 2019, our hand pleated plissé is now Azur’s signature. It was born from our meeting with two sisters, Véronique Arbué and Claire Raphaël, craftwomen, embroiderers, pleaters, and much more. The workshop was founded in Marseille (South of France) by Joséphine Pulvérail in 1900, where their mother Hortensia Arbué worked from 1957 to 1998, the year Véronique and Claire took over the family business, perpetuating a savoir-faire handed down from mother to daughter for generations.

The plissé is made entirely by hand, without molds or machines, and without the use of chemicals. The garment is placed on a table and sprayed with water. The pleats are folded one by one with the fingers until the piece becomes a closed fan. It is then rolled into a ball, wrapped into a piece of cloth and placed in a steam oven at 120 degrees for one hour. After the steaming, the garment is gently removed from its cloth wrapping and left to dry for a day or two. This artisanal process takes from 2 to 4 days to complete.

The result is a vibrant, irregular plissé, like sheets in the morning and wrinkles on the skin. It reflects light and enhances the silhouette. The body gives life to the garment, shaping it into unique living sculptures.

The earliest form of pleated dates from ancient Egypt and can be seen in a linen garment known as the Tarkhan dress, which is over 5000 years old and is believed to be one of the oldest dresses in existence. Differences in class and status in ancient Egypt were demonstrated by the fineness of the cloth, with many garments laid out in the sun and bleached white, before being enhanced with pleating.

ORGANIC, FAIR TRADE AND PEACE SILK

Cocccon was founded in 2012 by Chandra Prakash Jha in Jharkhand (India) with the aim of creating high quality and sustainable silk fabric with respect for people, animals and the planet. This collection is composed of organic and fair trade satin, raw, muga and organza peace silk fabrics.

Following the invention of artificial silk (viscose) in the 19th century, and the development of its industry, silkworm rearing for the production of silk thread completely disappeared in France. French mills still weave silk today, but the raw material is imported from Asia. Information on the origin and conditions of silk production is very complicated to obtain from these mills, and often very abstract. To ensure traceability, transparency and make sure to meet Azur’s values, we have chosen to work with a manufacturer involved in the entire production process: tree cultivation, worm rearing, spinning and weaving.

Silk is an animal byproduct, made from the cocoon filaments of domesticated silkworm. Traditionally, harvesting these cocoon filaments involve boiling the silkworm while it’s still alive. This makes it easier to extract and collect the silk fibers, but obviously means a very cruel and painful ending for the caterpillar. Alternatively, peace silk (or ahimsa silk) allows the silkworm to mature into a moth and fly out of the cocoon. This process saves lives of silk moths but also requires 1/4rd of the water for degumming compared to conventional silk. Since cocoons are without impurities, need of using hard-metal chemicals related to killing germs or removing impurities are also not required. Moths contribute in local pollination in the same way as bees, which is very important for local botanical life cycle.

pictures: Cocccon

MERINO WOOL HAND FELTING

We are proud to introduce in our last collection our first wool felt pieces. They are made of Mérinos d’Arles wool (Merino wool), a fine and very soft wool from Provence region (South of France) transformed into felt by matting, condensing, and pressing the fibers together. The felting is hand-made in Marseille (South of France) by Azur’s founders Lisa and Lisa with the help of Ghislaine Garcin, wool felter.

In the wet felting process, hot water and Marseille soap are applied to layers of animal hairs, then the properly arranged fibers are wrapped in a sturdy, textured material, such as a bamboo mat or bubble wrap. Repeated agitation and compression causes the fibers to hook together or weave together into a single piece of fabric. This artisanal process takes many hours to complete.

Felt from wool is one of the oldest known textiles. Felt’s origins can be found in central Asia, where there is evidence of feltmaking in Siberia (Altai mountains) in Northern Mongolia and more recently evidence dating back to the first century in Mongolia. Siberian tombs (7th to 2nd century BC) show the broad uses of felt, including clothing, jewelry, wall hangings, and elaborate horse blankets.

The Merino is a breed of domestic sheep, characterised by very fine soft wool. It was established in Spain near the end of the Middle Ages. The Mérinos d’Arles (meaning Merino of Arles) is a breed of sheep bred for wool, created in southeastern France during the 19th century by crossing local ewes with Spanish Merino rams.

WOVEN IN FRANCE ORGANIC COTTON-LINEN FABRIC

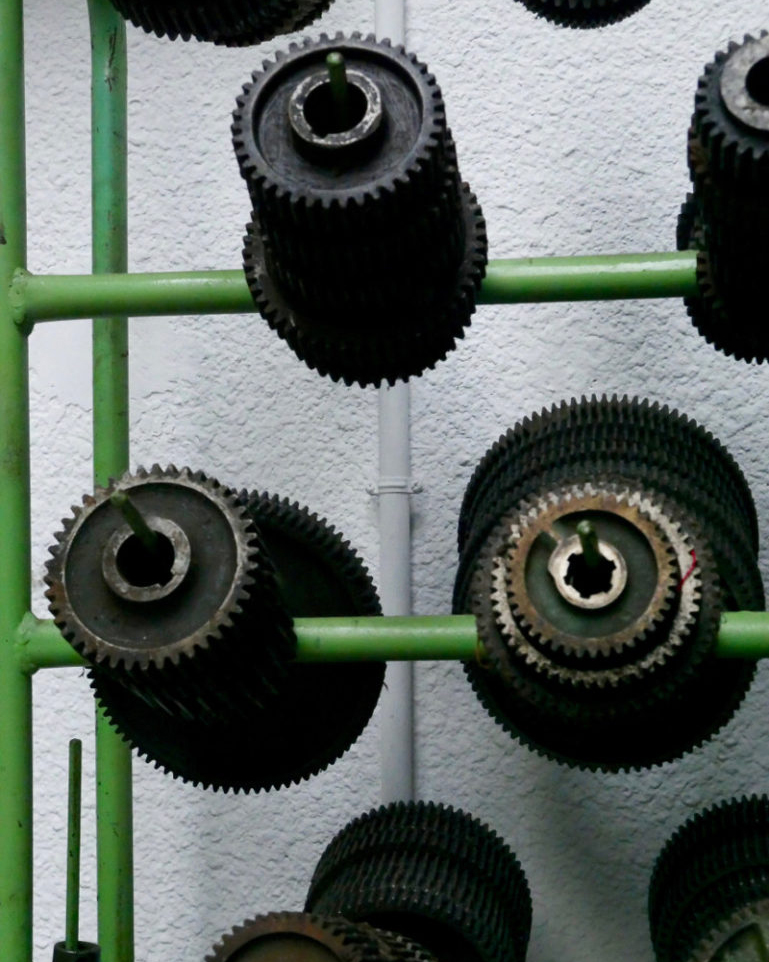

Manufacture Métis is a French weaving mill built in 2016 by Cédric Plumey in Etupes (North Est of France). A large selection of vintage textile machines (from 1892 to 1970) from every corner of France have been gathered and restored to be useful again. Every steps of preparation and weaving are carried out in-house, from yarn bobbins to the cloth. Fabrics are woven out of a selection of natural fibers only. Cédric owns a vast archive of thousands of vintage and antique cloth samples from which it takes its inspiration when designing new fabrics.

Manufacture Métis aims to produce modern yet durable fabrics, with the same quality and robustness as those made a hundred years ago in France.

For our last collection, we chose to work with a fabric known as Métis (meaning mixed) made with a pure organic cotton warp and a pure linen weft. Métis was very common in France in the last century and used to make bed sheets, pyjamas, undergarments and so on. Métis arrived on the French market in the early 1900s with the appearance of heavy, monogrammed, handembroidered fabrics. The combination of cotton and linen makes métis fabric very strong, and keeps it looking neat and delicate. The fabrics made over a century ago, were designed to be washed by maids kneeling at village laundries and hammered on flat stones. Before the invention of bleaching agents and detergents, linen was not hung out to dry, but laid flat on the ground in meadows, so that the chlorophyll present in the grass leaves would naturally bleach the fabric as it dried.

pictures: Manufacture Métis